CCD Cameras¶

SES¶

Pumping SES¶

turn cryotiger off, port 8 on pdu4 = 161.72.132.92

turn on power for vacuum pump and valve, port 3 and 4 on pdu4.

This is easiest with vncviewer to wifsip/archive, open a browser there and type in the IP address in the URL line.

If asked for password, user is apc. Not the standard password.

set temperature to 40, temperature sensor to 1 as root@ses

cd src/sci-ccd231-ses

./set_temp localhost 40 40 40 40

./set_tsens localhost 1

no need to wait until temperature is rather high.

turn pump on on archive.

~/bin/pfeiffer-test.py –switchon

watch pump speed.

~/bin/pfeiffer-test.py ;

output like

001500 0011030906001500026

000000 0011001206000000011

001 0011003003001121

first number is pump speed (1500). It will take a few minutes to reach full speed.

open valve when pump speed is approaching 1500, on archive

~/bin/pfeiffer-test.py –openvalve

speed will decrease immediately, pressure will jump up (the sensor is on the pump side of the valve)

watch pressure and pump speed, pressure should never go up, pump speed should go back up to 1500 after some time. It helps to close the valve for a few time for a few minutes until the speed settles

watch pressure: archive: ~/bin/ses_readpress.py

output like

SES: 0.009172 mbar Pump: 14.151923 mbar | T_CCD: -120.04K T_CAR: -117.44K T_x: -146.66K T_COLD: -162.60K

first number is pressure (0.0012)

watch pump speed: archive: ~/bin/pfeiffer-test.py

wait until temperature is 40 for some time and pressure <= 10-5. This will take some hours to reach.

set temperature to -120, on ses

cd src/sci-ccd231-ses

./set_temp localhost -120 -200 -120 -120

./set_tsens localhost 0

turn cryotiger on at pdu4

wait as long as possible (coldhead temp at least -60)

close valve:

~/bin/pfeiffer-test.py –closevalve

turn off pump

~/bin/pfeiffer-test.py –switchoff

turn off power to vacuum valve and pump on pdu4

WiFSIP¶

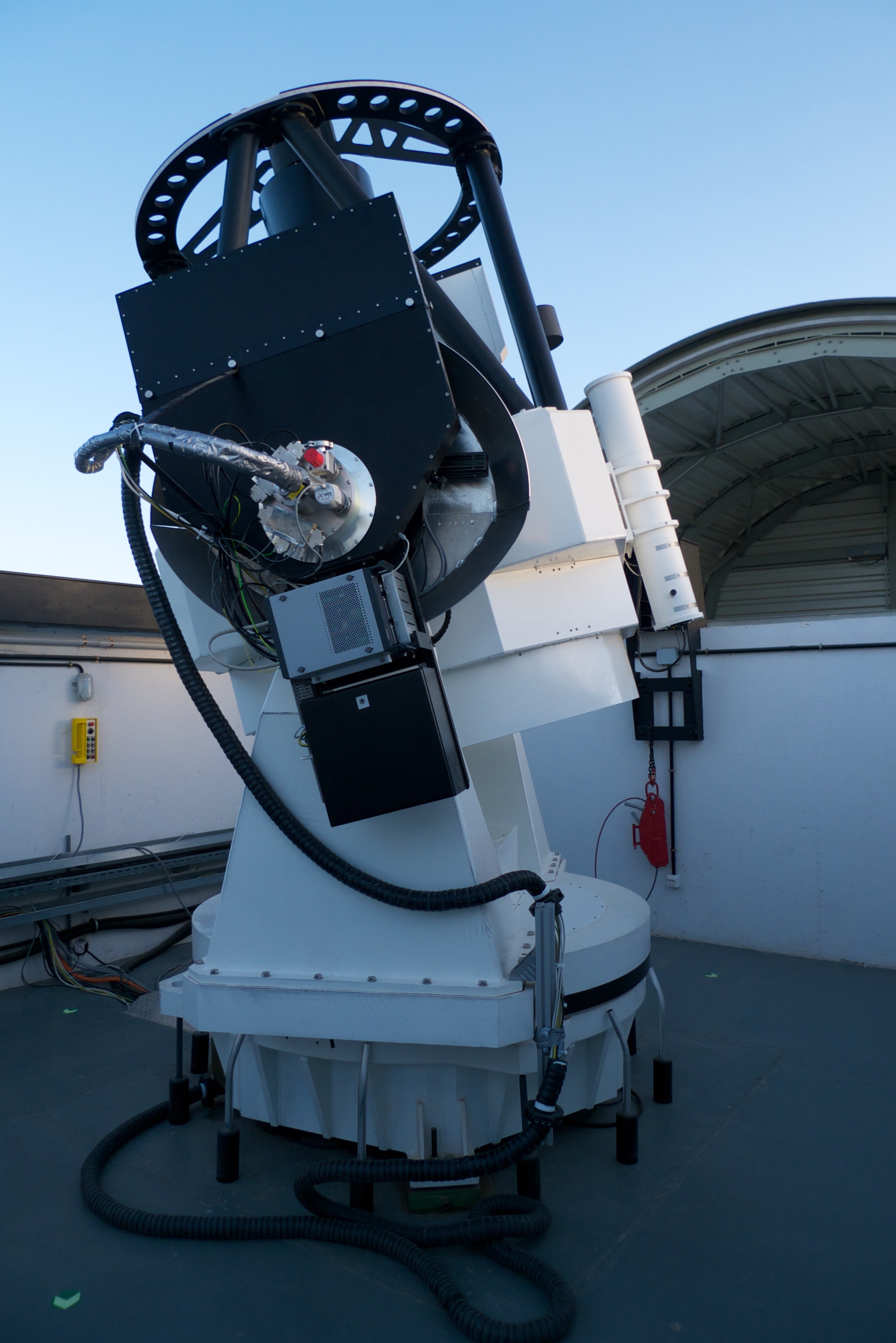

The STELLA-I telescope during operation with the WiFSIP instrument in front.¶

WiFSIP CCD¶

Voltages of the WiFSIP CCD power supply¶

15V: V1=15V, V2=15V

5V: V1=5.35V, V2=5.20V

30V: V1=30.5V

48V: V1=48V

Pumping WiFSIP CCD system¶

The vacuum in the CCD dewar needs to be maintained. Especially after extended power outages, pumping the dewar is necessary. The following steps are necessary:

Preparation¶

AIP - The cooling system (the Cryotiger / PCC compressor) needs to be turned off, and the CCD should be heated to room temperature to avoid condensation on the CCD (it could otherwise end up being the coldest spot in the dewar)

AIP - move the STELLA1-derotator so that the vacuum flange points downwards.

Pumping¶

put the vacuum pump onto the table next to the telescope as seen in the picture. Connect the vacuum hose.

Turn on the vacuum pump. Wait until it reaches about 1.E-3

Open the Valve

Keep pumping for as long as possible.

Please alert AIP personal at least 2 hours before stopping. The cooling system need to be started then.

Make note of the final pressure. Should be around 1.0 E-6

Close Valve

Turn off pump

Wait for it to stop moving, then disconnect

Cleaning the WiFSIP cold head¶

If the cooling performance degrades, a possible cause can be contamination in the cold head.

This is an experimental recipe for cleaning the coldhead:

Attaching the two external valves with the N2 hose on the supply side and the vacuum hose on the return side.¶

Turn off the cooling system (Cryotiger / PCC compressor)

Note system pressure

Set the CCD temperature to room temperature to avoid condensation and let system warm up for several hours

Remove gas tubes at the CCD cold head, put protective covers on valves.

Connect valve with pressured air hoses to supply, valve with vacuum hose to return

Open valve on return side, gas will escape audibly

Connect N2 at the supply side, and flood the cold head with N2 gas for about 1 minute.

Close valve on supply side, turn off N2 at bottle

Connect vacuum pump on return side and vacuum the cold head. Reachable pressure is about 1mbar.

Close return valve, disconnect vacuum pump and long hose, connect short hose instead (keep valve in place)

Attach short pressured air tube on supply side (instead of long one, but keep valve in place!), fill it with ISO-Propanol / Ethanol or mixture

Slowly open valve on supply side, re-fill ISO / Ethanol when needed - total volume is about 150ml, the solvent gets sucked into the cold head

Let sit for at least 30 minutes

Switch valves, connect long pressured air hose (remove short one first) at return side and connect N2

Open supply valve (where short vacuum hose is connected), then open return (N2) valve

Flood system with N2 for at least 30min. Carefully rotate derotator while flooding. No fluid should be visible at the short vacuum tube on the supply side.

Close valve on return side, then close valve at supply side.

Attach long vacuum hose on supply side (remove short one first), connect pump, turn on, open supply valve, and vacuum the cold head.

Close valve on supply side

Remove vacuum tube & pump, remove valve on supply side

Attach PT-14 bottle on supply side and open it’s valve. Head will fill with PT-14.

Remove PT-14 bottle

Remove pressured air hose, N2 bottle, remove valve on return side

Re-attach hoses to cold head

Note system pressure

Pump CCD system and re-start cooling system